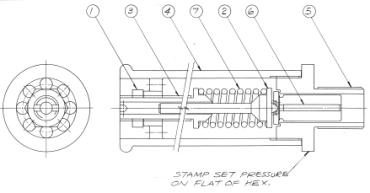

Safety Valve Design

Faced with operational problems created by the use of safety valves made by utilising components from industrial units which had poor operating characteristics we were asked to design replacements. The key issues were the large hysteresis in the valve opening and closing characteristics, which resulted in either the use of reduced boiler pressures by engine crew or continual feathering of the valve in service both of which were fuel inefficient, and the sideways venting of the steam, which could obscure the drivers line of sight at critical moments. The solution was to design new, visually attractive, 'Pop' safety valves with only 5 psi hysteresis and conventional vertical discharge to ensure that vented steam went over the cab roof.