New Locomotive for Perrygrove Railway

We were requested by locomotive builders Alan Keef Ltd to prepare a specification and concept design for a new locomotive for the Perrygrove Railway.

The railway which is steeply graded with two sections of 1 in 30 and a minimum radius of curvature of 44ft required a more powerful locomotive to enable them to increase their maximum train length from 3 to 4 carriages while also facilitating ease of operation and maintenance.

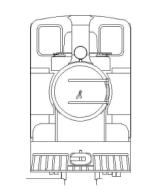

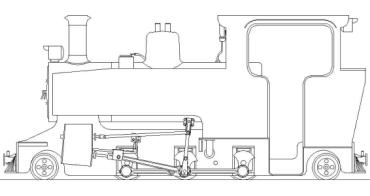

After visiting Perrygrove and discussing their requirement in detail, we prepared a specification and undertook the fundamental design calculations and computer modelling of the proposed locomotive to achieve the required performance. This culminated in the preparation of an outline design drawing for the complete locomotive.

Design details

A 2-6-2 wheel arrangement was selected with the leading and trailing pony trucks providing good guidance for the locomotive when entering a bend running either forwards or backwards. The centre coupled axle has flangeless wheels to facilitate negotiating the tight bends without excessive flange friction.

In addition the tight radius curves dictated that minimising the overall length of the locomotive and overhung weight at the extreme ends was desirable to reduce the tendency to yaw laterally on entering or leaving the line's tight curves. This has influenced the boiler design which incorporates a narrow firebox with a sloping grate over the rear driving wheels thus ensuring that the large diameter, short barrel boiler is well supported and the overhang at the rear of the engine is minimised giving good weight distribution.

For good ride quality, self damping elastomeric springs are utilised throughout and these avoid the possibility of fatigue failures associated with the use of leaf springs.

For ease of manufacture and maintenance, slide valves have been selected in preference to piston valves as for this low speed hill climbing application the performance of the locomotive will not be compromised. The use of balanced valves reduces frictional losses and wear on the valve gear.

The valve gear is Hackworth with a curved die block slide to improve valve gear geometry and valve events. The valve gear design was optimised for 30% cut-off in forward gear with a full gear cut-off of approx 70% for easy starting whilst providing long travel motion for the valves to ensure good steam flow at short cut-offs.

All the motion and axlebox bearings are rolling element grease lubricated units for low friction and ease of maintenance.

The locomotive is provided with a four nozzle Lempor exhaust system to keep exhaust back pressure to a minimum and a four-jet blower is incorporated into the blast nozzle assembly.

Mechanically operated sanding gear is fitted with sand being stored in a boiler mounted sandbox for warmth to keep it dry. The sand is applied between the first and second driving axle to facilitate both forward and backward operation with only one set of sanding gear.

Construction and commissioning

The aesthetic and detail design was undertaken by Alan Keef Ltd and the final pleasing appearance is shown in the accompanying illustrations. The locomotive was constructed at Keef's Ross-on-Wye works with Steam Loco Design continuing to provide design advice.

The locomotive was delivered to Perrygrove in October 2008. It has since undergone commissioning trials and entered service after receiving type approval from HMRI who commented very positively on the ride quality.

Operational experience

The completed locomotive has proved popular with locomotive crews and the Railway's owners alike and has been the motive power of choice since delivery.

Lydia's regular Driver has commented that at Easter, after the Railway's second busiest day ever, that he could not believe quite how efficient the locomotive was as steam raising and 11 return trips were achieved with the consumption of only four and a half buckets of coal. In addition he reports that she has proved a pleasure to drive, easy steaming and comfortable and that even after a busy day standing on the footplate he goes home feeling comfortable and relaxed. These sentiments are echoed by the Railway's owner, Michael Crofts, who estimates that the improved fuel efficiency will save him around £800 p.a.

With the locomotive booked to attend the Bure Valley Railway Gala on the 10-11th October 2009 there will be an exciting opportunity to see Lydia put through her paces in a different environment with switch back gradients, bigger trains and a higher line speed.