New steam driven air pump designed to provide a reliable source of compressed air for both single and twin line air braking systems and featuring the use of modern seal materials for low maintenance in service.

Steam Driven Air Pump

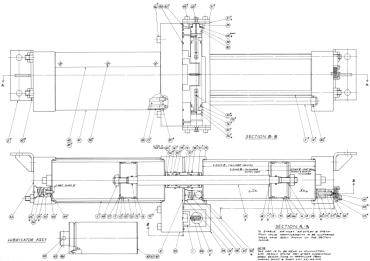

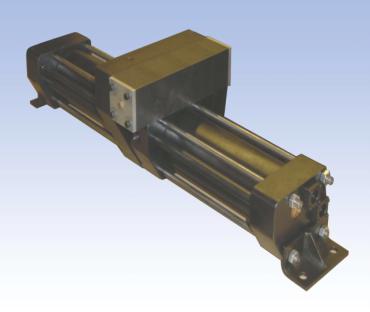

These modern brake pump units have been designed to provide a reliable source of compressed air for both single and twin line air braking systems on new and historic steam locomotives. The pumps are constructed to a high standard and feature the use of modern seal materials for low maintenance in service.

The pumps can be supplied in a number of sizes to suit the quantity of air required and are suitable for mounting in a variety of orientations enabling the units to be positioned where appropriate on the locomotive. This versatility of mounting makes it relatively easy to conceal the pump on historic locomotives which were not originally fitted with compressed air braking.

A starting valve is incorporated as standard to ensure easy reliable operation from rest when either hot or cold and the only daily care required is to keep the lubricator, which is supplied with the pump, topped up with steam cylinder oil.

Periodic maintenance is only required at very infrequent intervals after extended periods of operation. To completely refurbish the pump normally only requires the replacement of the seals within the unit and re-lubrication of the air cylinder. A full seal and lubricant kit is available and the work can be easily undertaken using only hand tools.

Currently only smaller units for narrow gauge locomotives have been constructed but larger pumps suitable for standard gauge locomotives with higher boiler pressures could be designed to suit customer's needs using the same technology.

A derivative of this pump which provides a more traditional 'Westinghouse' external appearance is being planned for the near future aimed at the large scale miniature locomotive market.